Track Cleaning - NEW IMPROVED CMX OPERATION!

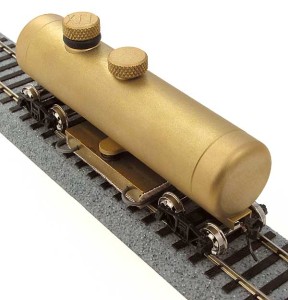

CMX HO Scale Shown

What to do:

We tried mixing 5% (by volume) of DeOxit D100L (the full strength stuff) with 95% (by volume) of 91% isopropyl alcohol. We then ran this solution in a HO scale CMX Clean Machine on our maintenance train. The alcohol removes most of the grease/oil/debris. The DeOxit removes the metal oxides that are interfering with electrical contact. Previously, the oxides had to be removed by mechanical abrasion (i.e. sand paper or track block). We are using a 5% solution of DeOxit at the Shelburne Museum. The trains have never run this reliably before. We use it on both track and wheels. A damp pad of this solution under an engines's pickup wheels works wonders to restore smooth operation.

There is a slight down side. The DeOxit in combination with the really clean metal track causes a 10% (estimate) loss in tractive effort (wheel slip) of the engine for a short time after cleaning. We imagine that the clipper oil some folks use has a similar (and probably longer term) impact.

However, a 25ml bottle of DeOxit D100L dumped into a pint bottle of 91% isopropyl alcohol and shaken is almost exactly a 5% solution (which is not a critical target).